RECYCLING BATTERIES

STEP BY STEP INSTRUCTIONS

THESE GUIDELINES ARE TO ASSIST IN COMPLIANCE WITH FEDERAL DEPARTMENT OF TRANSPORTATION (USDOT) REGULATIONS. PLEASE ASSIST THE DRIVER IN COMPLYING WITH THE LAW. FAILURE TO COMPLY WITH THE GUIDELINES CAN RESULT IN REFUSAL BY THE CARRIER TO ACCEPT MATERIAL. IN ADDITION, FAILURE TO COMPLY CAN RESULT IN FINES AND PENALTIES FROM FEDERAL, STATE, AND LOCAL AUTHORITIES.

*THESE GUIDELINES ARE PROVIDED FOR REFERENCE ONLY. PLEASE REFER TO YOUR LOCAL GOVERNING BODY FOR REQUIREMENT UPDATES.

Download MK Battery

Spent Batteries Request Form PDFDownload Complete Packaging &

Securing Used Stationary Batteries PDF

Information provided by MK Battery and Deka Unigy.

View specific requirements below:

- View listing of MK Battery and East Penn DEKA branch locations that will accept spent batteries.

- When returning the battery to the provider or retailer that you purchased from, most of these locations will accept these back and return them for recycling.

- Most local townships or cities work with the local waste disposal companies in many areas and have periodic “household hazardous waste pickups” where they will collect electronics, batteries and other chemicals for recycling.

- Visit Call2Recycle for a listing of locations throughout the United States that accept batteries back for recycling. Note, for lead acid batteries they only accept sealed, non-spillable batteries that weigh less than 11 pounds. The Rechargeable Battery Recycling Corporation (RBRC)’s Call2Recycle program is a nonprofit, public service organization funded by rechargeable product and battery manufacturers that educates manufacturers, retailers, and consumers about the benefits of rechargeable battery recycling.

- For additional locations or large quantities for recycling you may contact MK Battery customer service group at 800-372-9253 and they will find a location near you.

IMPORTANT SKID/PALLET SPECIFICATIONS

Use a skid/pallet provided with a new shipment to return used batteries if possible

Use a skid/pallet provided with a new shipment to return used batteries if possible

- Maximum skid/pallet sizes: 48″ x 44″ or 48″ x 40″

- Skid/pallet boards: 5/8 inch thick minimum preferred

- Skid/pallet must be constructed with a minimum of three bottom runners

- Skid/pallet sturdy and durable enough to handle the weight of battery load

Before handling battery/cell(s), please read and adhere to all of the following requirements:

- Wear the appropriate personal protection equipment

- Handle all returned batteries with the same responsible care as new batteries

- Keep batteries upright at all times. Do not tip over on side or upside down (Except Non-Spillables)

- Do not drop batteries. Put batteries carefully down on skid/pallet

- Only lead-acid batteries may be returned

- Do not double stack cells or batteries on skid/pallet

- Terminals must be protected with non-conductive caps, tape or other insulating material (e.g. waffleboard, cardboard) to prevent shorting

- Total height of package not to exceed 1 1/2 times the skid/pallet width

- Any damaged or cracked cell must be free of electrolyte and placed in a heavyweight clear polyethylene plastic bag (min. 6 mil) that is securely closed.

- All vent caps must be in place

IMPORTANT GENERAL HANDLING REQUIREMENTS

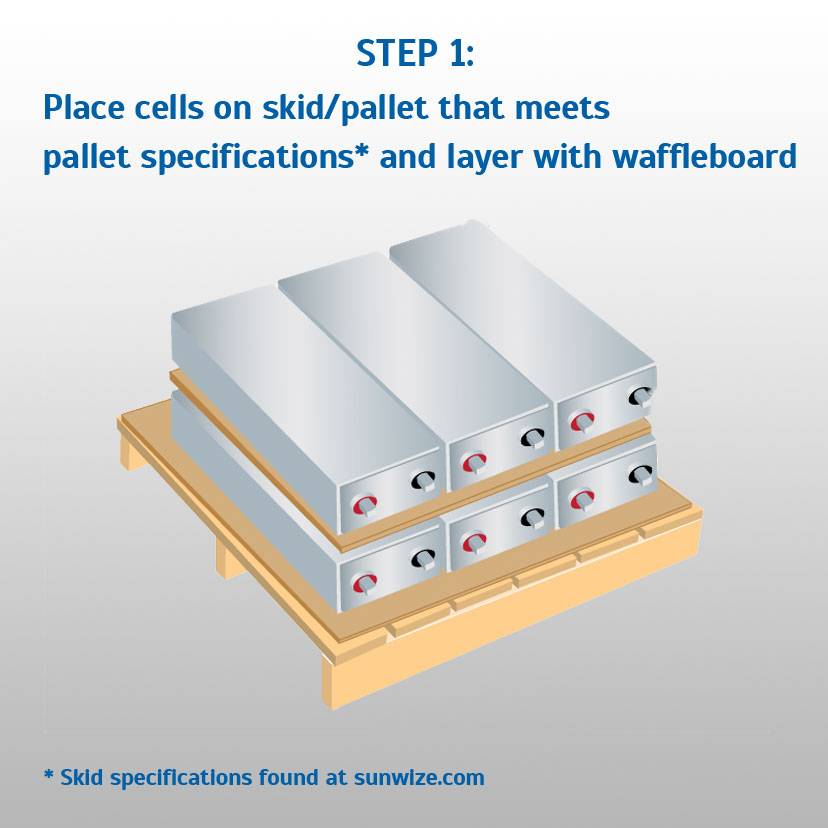

INSTRUCTIONS FOR STACKING USED STATIONARY MONOBLOCK BATTERIES

- Select a sturdy skid/pallet with no broken or missing boards. (See “Skid/Pallet Specifications” for details).

- Be sure there are no nails sticking up, which could puncture the batteries. Stack return battery pallet using pallet provided with new shipment if possible.

- Place a layer of cardboard on the pallet to prevent the batteries from sliding off of the pallet.

- Make the first layer of batteries level and as close together as possible. If some of the batteries are shorter, they should be placed in the center of layers. Any taller batteries should be placed on the top layer.

- Place waffleboard (preferred) or sufficient cardboard (multiple sheets if necessary) between all layers, including the top layer of batteries to prevent the possibility of puncturing the batteries above and short circuits. Place cardboard on top of pallet.

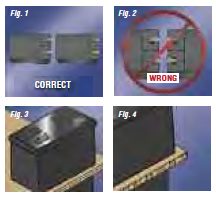

- Batteries with terminals on the side must be stacked so the posts are facing away from each other and not facing towards the outside of the pallet. Terminals on the side must never touch.(see Fig.1 and 2)

- Terminals on the top must be positioned toward the outside of the pallet so the layer above it leans toward the center.(Fig. 3)Make sure that no batteries are overhanging the waffleboard or sheets of cardboard.(Fig. 4)

- Stud terminal batteries should be on the top layer. If this is not possible, you will need extra layers of cardboard between the layers of batteries to prevent punctures.

Preparing Used Non-spillable stationary cells for shipment

INSTRUCTIONS FOR WRAPPING USED STATIONARY MONOBLOCK BATTERIES FOR SHIPMENT

All batteries must be secured to the pallet with stretch wrap. Stretchwrap works best if it is pulled tight before stretching it around the corners.- Start with the stretch wrap turned sideways to create a rope effect (see fig. 1.) Wrap around the top layer at least twice.*

- Still using the rope effect, wrap the top layer twice* again, crossingover the top each time to form an “X-pattern.” This will pull the batteries towards the center to prevent batteries from falling off of the pallet, a DOT requirement.

- Hold the stretch wrap open (see fig. 2 and 3), wrap around the bottomlayer twice*, being sure to catch the edges of the pallet.

- Finally, after placing cardboard on top of the batteries, wrap around the top layer twice* with the stretch wrap in the open effect and tear at the last corner.

*Wrap as many times as necessary to stabilize the load

INSTRUCTIONS FOR PREPARING USED NON-SPILLABLE STATIONARY CELLS FOR SHIPMENT

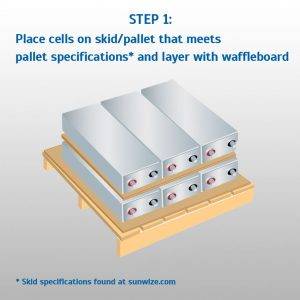

- Place cells on skid/pallet that meets pallet specifications noted in this document. Use Triwall (3 Layer Cardboard) or Waffleboard between layers.

- Place 1/2” plywood sheet on the top of pallet. Place your first layer of cells on top of the plywood.Place cells on their side to help avoid the possibilityof them falling over during shipment. Place one layer of 5/8” Triwall or Waffleboard on the top of the first layer of cells. Place the next layer using the same guidelines. Continue building layers, making sure that you do not exceed maximum pallet weight.(See Step 1). Place Triwall or Waffleboard around ALL sides of the cells.

- Secure the cells by nailing wooden cleats to the skid on all sides so the Triwall is held tightly against the cells and will remain vertical.

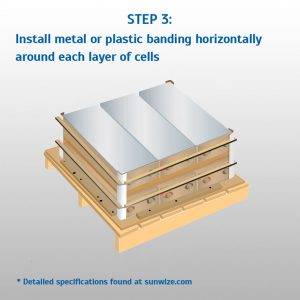

- Install cardboard corner supports initially with packing tape to make it easier to manage before banding(See Step 2).

- Install metal or plastic banding 2 horizontally around each layer of cells as shown in drawing (Step 3). Before pulling tight, place wooden strips under the banding as shown to provide support for the cardboard. Note, the wooden strips can be held inplace with packing tape to make it easier to manage before tightening the banding.

- Once each layer has one horizontal band securing them, place 1/2” plywood on the top layer and secure with two bands vertically that run from front to back on the skid. Drill holes through cleating/skid boards as close to cells as possible and run banding through holes and around batteries to secure.

- After you have completed banding, place the RSA tag on top of the pallet to complete preparation for shipping (See Step 4).

Title 49 C.F.R. 173.159 Batteries, Wet2PLASTIC BANDING SPECIFICATIONS: • PREFERRED: 3⁄4″ polyester strapping, 2500 lb break strength – utilizing friction weld, NOT clips • LIGHT WEIGHT APPLICATIONS: 5⁄8″ polyester strapping, 1400 lb break strength – utilizing friction weld, NOT clips • ALTERNATIVE MATERIAL (Manual Application): 3⁄4″ polyester composite strapping, 2000 lb break strength – buckle joint

Download Complete Packaging and Securing Used Stationary Batteries PDF