Understanding Temperature Effects on Crystalline PV Modules

Battery Charging

The first thing to understand in this discussion is that lead acid batteries are charged by current, not voltage. The voltage of the solar array only needs to be high enough to allow current to flow, any extra voltage is power that is left unused in the solar array. A Maximum Power Point Tracker (MPPT) controller extracts this extra power from the solar array and converts it to additional current to charge the battery (this will be addressed in greater detail further in this document). If the voltage from the solar array is not sufficiently high compared to the battery voltage, current will not flow and the battery will not get fully charged.

Leaving a lead acid battery at a low state of charge for an extended period of time will cause sulfate crystals to form on the plates and will reduce the capacity of the battery causing the battery to fail prematurely.

Voltage Between Array & Battery

Second, you need to understand why the Maximum Power Voltage (Vmp) of a solar module is so much higher than the battery voltage. Most nominal 12V PV modules have a Vmp of 17-19VDC at Standard Test Conditions (STC) and consist of 36 solar cells wired in series. Most nominal 12V Valve Regulated Lead Acid (VRLA) batteries have a charge voltage of 14.1-14.4VDC.

There are three main reasons for voltage drop:

• Line loss (voltage drop in wires). 5% in a 12VDC system is 0.6VDC.

• Controller loss (voltage drop in diodes and transistors). 0.5 to 1.2VDC depending on the controller.

• Module voltage loss due to temperature. Up to 4VDC at 50°C (depending on voltage & temperature coefficient of specific solar module).

If you add up the voltage losses, they range from 1VDC to over 5VDC (depending on temperature and charge controller used). If the module Vmp is 18VDC and the total voltage loss is 4VDC, only 14VDC is left to charge the battery. The minimum charge voltage for a 12VDC VRLA battery is 14VDC.

With the module voltage loss from temperature being the single largest loss in the calculations, it’s important to understand this loss and how it effects the solar system and battery charging.

STC vs NOTC

Third, you need to understand how modules are rated and the difference between STC and NOCT.

• STC = Standard Test Conditions:

irradiance of 1000 W/m2, spectrum AM 1.5 and cell temperature of 25°C

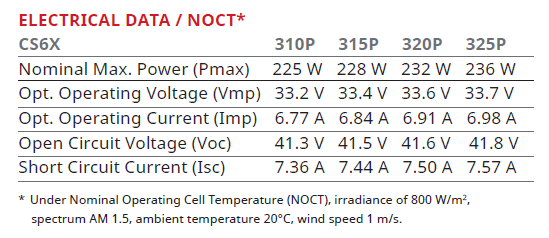

• NOCT = Nominal Operating Cell Temperature: Irradiance of 800 W/m2, spectrum AM 1.5, ambient temperature 20°C, wind speed 1 m/s

STC is more of a lab created scenario; whereas, NOCT is closer to reality. Note two main items:

1) STC is at 1000 W/m2 and NOCT is at 800 W/m2. This is the amount of sunlight that strikes the surface of the solar module and represents a 20% reduction in power just based on this one variable.

2) STC is rated at cell temperature and NOCT is rated at ambient temperature. This is important to note as it has a direct impact on the output voltage and power and will be discussed further in the following paragraphs.

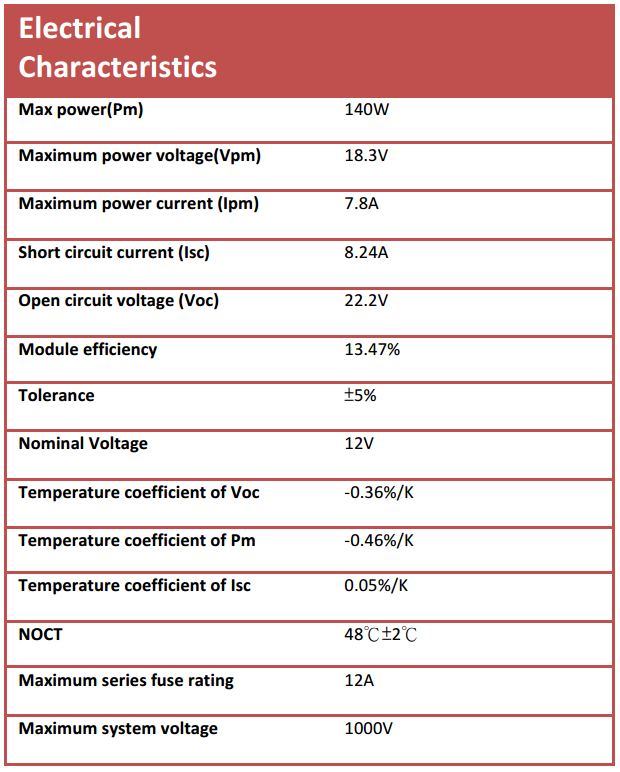

Using the Solartech SPM140P-F as an example:

• Voc = 22.2VDC at STC

• Vmp = 18.3VDC at STC

• Temp. coefficient of Voc = -0.36%/°C at STC

• NOCT = 48°C +/-2°C

So based on the NOCT number above, there is a 28°C difference ambient and cell temperature (48°C-20°C=28°C). If you applied that to a cell temperature of 25°C (STC rating) that would equate to an ambient temperature of -3°C. Not a very real world situation, as in most locations and year round the average daytime ambient temperature is going to be greater than 0°C. This, along with the 20% reduction in irradiance, constitutes most of the reason array output production more closely approximates NOCT and not STC. This is one of the reasons NOCT ratings were developed, to more closely approximate real world variables.

Temperature Compensation Calculations

To better understand the impact, lets run through some calculations using the above numbers.

22.2Voc x -0.36%/°C= -0.07992V/°C.

At an ambient temperature of 50°C the cell temperature is 78°C.

78°C – 25°C (STC) = 53°C x -0.07992V/°C = -4.23V.

This would reduce the module Vmp to approximately 14V (18.3-4.23=14.07V), and Voc to 18V (remember Voc is at 0A, no current). Note this is before any additional losses of voltage drop in the wires or charge controller!

MPPT and PWM Examples

Now referring back to the MPPT controller mentioned earlier, in this example there is no extra voltage to extract power from the module, so the MPPT would be of little or no benefit. However, this example is at an extreme temperature of 50°C, so what happens at more normal operating temperatures.

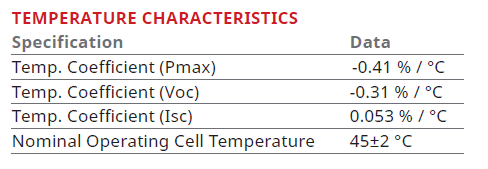

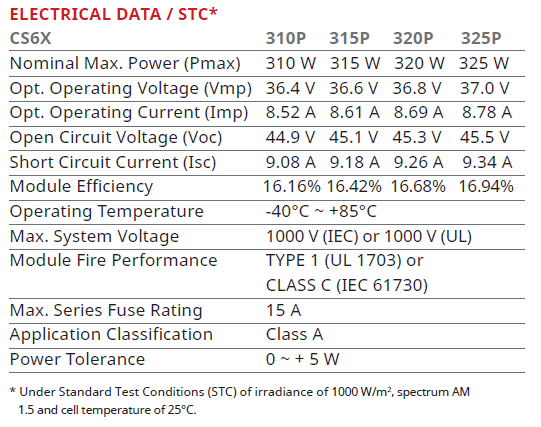

For the following example, let’s use the Canadian Solar CS6X-320P PV module, whose data sheet vales for temperature characteristics, STC, and NOTC are shown below.

MPPT Example

As the MPPT controller is trying to extract power from the module let’s begin with those calculations and let’s use an ambient temperature of 25°C, which is fairly close to normal operation.

320W x -0.41%/°C = -1.312W/°C

At an ambient temperature of 25°C the cell temperature is 50°C.

50°C – 25°C (STC) = 25°C x -1.312W/°C = -32.8W

320W-32.8W = 287.2W

The typical battery charge voltage of a 24V nominal VRLA battery is 28.56VDC

287.2W/28.56VDC = 10.0A of charge current from an MPPT controller.

PWM Example

A PWM charge controller would just pass through the maximum current available, which could be up to 9.26A (Isc value of the 320W module from the STC datasheet above).

10.0A – 9.26A = 0.74A, which is a 7% increase in output current from the MPPT charge controller over the PWM controller.

Conclusion

The temperature has a large impact on the output voltage and power from a crystalline PV module. This impact is linear and increases with temperature. In high temperatures, modules with insufficient voltage may be unable to fully charge a lead acid battery.

As additional unused power in PV modules is reduced in high temperature, so is the advantage of MPPT charge controllers. Therefore, even at normal operating temperatures, the additional extracted power of an MPPT charge controller compared to a PWM controller can be minimal.

Use the knowledge in this Tech-Note to:

- calculate what the expected power output and voltages are of modules under various temperature conditions.

- Determine whether your batteries will get sufficiently charged in these conditions.

- Compare the potential advantages of an MPPT controller over a PWM controller by calculating the expected power output of both and comparing them.